Top Steel Tank Fabrication Suppliers in Saudi Arabia | Precision & Quality

Explore premier steel tank fabrication suppliers in Saudi Arabia, offering precision-engineered and high-quality steel tanks for various industrial and commercial applications. From storage tanks to custom-fabricated solutions, Kingdom Gratings suppliers provide robust and reliable products designed to meet your specific requirements. Utilizing advanced fabrication techniques and adhering to stringent quality standards, they ensure each steel tank delivers superior durability and performance. Whether you need tanks for liquids, gases, or specialized purposes, trust these experts to deliver top-notch solutions that enhance your operations. Discover exceptional steel tank fabrication services and elevate your infrastructure in Saudi Arabia.Contact us for more info

Introduction to Steel Tank Fabrication in Saudi Arabia

Historical context of the industry

Hey there! Let’s take a trip down memory lane and explore how steel tank fabrication in Saudi Arabia came to be. It’s a story that goes hand in hand with the country’s oil boom. Back in the 1930s, when oil was first discovered, the need for storage tanks skyrocketed. At first, most tanks were imported, but as the industry grew, so did the local expertise.

Current market overview

Fast forward to today, and wow, has the market changed! Saudi Arabia is now a major player in steel tank fabrication. The industry has grown by leaps and bounds, with local companies producing top-notch tanks for various sectors. It’s not just about oil anymore – we’re talking water storage, chemicals, and even food processing.

Importance of steel tanks in Saudi Arabia’s economy

You might be wondering, “Why are these tanks such a big deal?” Well, let me tell you – they’re the unsung heroes of Saudi Arabia’s economy. Without them, storing and transporting oil, the country’s main export, would be a nightmare. Plus, they’re crucial for water storage in this desert climate. It’s safe to say that steel tanks are the backbone of many industries here.

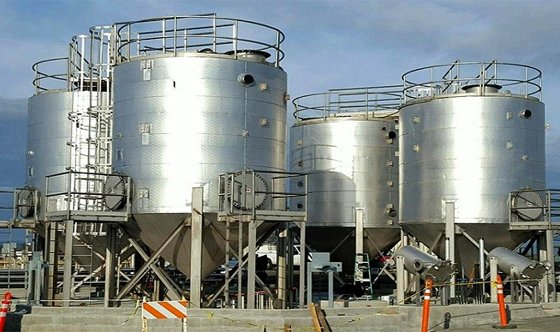

Types of Steel Tanks Produced in Saudi Arabia

Storage tanks for oil and gas industry

Oil and gas storage tanks are the bread and butter of the industry here. These tanks come in all shapes and sizes, from floating roof tanks that can hold millions of barrels to smaller fixed roof tanks. They’re built tough to withstand the harsh desert environment and the corrosive nature of oil.

Water storage and treatment tanks

In a country where water is precious, these tanks play a crucial role. They’re used for everything from storing drinking water to holding water for firefighting systems. Some are even designed for water treatment, helping to make seawater drinkable.

Industrial and chemical storage tanks

Last but not least, we have tanks for industrial and chemical storage. These are the tough guys of the tank world, designed to hold all sorts of substances safely. They’re used in factories, power plants, and even in the growing pharmaceutical industry.

Manufacturing Processes and Technologies

Raw material sourcing and preparation

It all starts with the raw materials. Most manufacturers source their steel locally or from nearby countries. Before anything else happens, the steel plates are carefully inspected and prepared. This might involve cleaning, cutting to size, or even heat treatment.

Cutting, shaping, and welding techniques

This is where the magic happens! Modern CNC machines cut the steel plates with incredible precision. Then, massive rollers shape the plates into cylinders. Welding is a crucial step – it’s done by skilled workers using advanced techniques like submerged arc welding.

Quality control and testing procedures

Quality control isn’t just a final step – it’s part of every stage of production. Welds are checked using x-rays or ultrasound. Tanks are pressure tested to ensure they’re leak-proof. Some companies even use drones for final inspections!

Challenges Faced by Saudi Arabian Steel Tank Manufacturers

Competition from international manufacturers

It’s not all smooth sailing for local manufacturers. They face stiff competition from international companies, especially those from China and South Korea. These foreign firms often have lower production costs, making it tough for Saudi companies to compete on price alone.

Meeting evolving industry standards

The goal posts keep moving when it comes to industry standards. New regulations pop up all the time, especially around safety and environmental protection. Keeping up with these changes can be costly and time-consuming for manufacturers.

Adapting to environmental regulations

Speaking of the environment, this is a big challenge for the industry. There’s growing pressure to reduce carbon footprints and minimize waste. Some companies are exploring eco-friendly coatings and more efficient production methods to address these concerns.

Future Outlook for the Steel Tank Fabrication Industry in Saudi Arabia

Emerging trends and technologies

The future looks exciting for steel tank fabrication in Saudi Arabia. We’re seeing a move towards smarter tanks with built-in sensors for real-time monitoring. 3D printing is also making waves, with some companies experimenting with 3D-printed components for tanks.

Potential growth areas and market expansion

There’s plenty of room for growth. The renewable energy sector, for example, is creating new demand for specialized storage tanks. Some manufacturers are also looking to expand into neighboring countries, taking their expertise beyond Saudi borders.

Government initiatives and support

The Saudi government is throwing its weight behind the industry. Programs like Saudi Vision 2030 aim to boost local manufacturing, including steel tank fabrication. There’s talk of more funding for research and development, which could lead to some exciting innovations.

Summary

And there you have it – a whirlwind tour of steel tank fabrication in Saudi Arabia! From its humble beginnings to its bright future, this industry has come a long way. It faces challenges, sure, but with innovation and determination, it’s set to keep growing and evolving. Who knew tanks could be so fascinating, right?

FAQ Section

- What are the main types of steel tanks produced in Saudi Arabia?

The main types are oil and gas storage tanks, water storage and treatment tanks, and industrial and chemical storage tanks. - How do Saudi Arabian manufacturers ensure the quality of their tanks?

They follow international standards like ISO 9001 and API 650, and use advanced testing methods like x-ray and ultrasound inspections. - What are the biggest challenges facing the industry? Competition from international manufacturers, keeping up with evolving standards, and adapting to environmental regulations are the main challenges.

- How is technology changing steel tank fabrication in Saudi Arabia?

New technologies like smart sensors, 3D printing, and advanced welding techniques are transforming the industry.

- What role does the government play in supporting this industry?

The Saudi government supports the industry through initiatives like Saudi Vision 2030, which aims to boost local manufacturing and innovation.

Diesel Tank Fabrication Manufacturersin Saudi Arabia

Find top diesel tank fabrication manufacturers in Saudi Arabia, specializing in the design and production of high-quality diesel tanks for various industrial and commercial uses. Kingdom Gratings offer custom fabrication services, ensuring each tank meets your specific needs for durability, capacity, and safety. With a focus on precision engineering and rigorous quality standards, they deliver reliable diesel tanks that perform consistently and stand up to demanding conditions. View More