Steel gratings suppliers & Manufacturers in Saudi Arabia

Leading Steel Grating Suppliers & Manufacturers in Saudi Arabia – Durable & High-Quality Gratings

Searching for reliable steel grating suppliers and manufacturers in Saudi Arabia? Kingdom Gratings, Saudi Arabia top-rated steel gratings are designed for strength and durability, perfect for industrial, commercial, and residential applications. With a commitment to quality and precision manufacturing, we offer customized grating solutions to meet your specific requirements. Contact us today for premium steel gratings from the best suppliers and manufacturers in Saudi Arabia!

Introduction

Welcome to our deep dive into the steel gratings industry in Saudi Arabia, a sector that, while might not grab daily headlines, plays a crucial role in the region’s industrial scene. Steel gratings, those ubiquitous metal meshes that support our steps, secure our machines, and guard our workers, represent a fascinating fusion of engineering and necessity.

In this post, we’ll explore the inner workings of the steel industry in Saudi Arabia, spotlighting the key manufacturers and the dynamics of this vital market. From the production processes to the latest innovations, and the protocols that govern quality – join us as we unfold the chapters of this intriguing industry.

The Fundamentals of Steel Gratings in Saudi Arabia

Definition and Applications: What are steel gratings and where are they used?

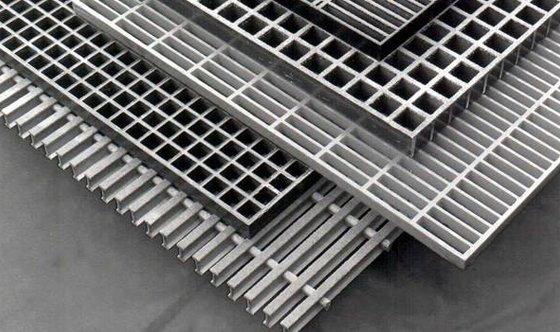

Steel gratings are designed as grid-like panels crafted from steel bars, used primarily for their durability and safety in industrial environments. Picture the walking surfaces on catwalks, the platforms on drilling rigs, or vents on your street – those are steel gratings hard at work. They offer crucial stability and protection in countless settings, including walkways, machine guards, and ventilation grilles.

Materials and Manufacturing: Common materials used and the manufacturing process

Primarily formed from carbon steel, stainless steel, or aluminum, these gratings can be manufactured through welding, pressing, or riveting. Welded steel gratings, for instance, blend load-bearing steel bars with cross rods using high heat to ensure uniform strength and durability.

Types of Steel Gratings: Differentiating between press-locked, welded, and riveted gratings

Each type of grating offers unique benefits:

- Press-locked gratings are noted for their smooth, aesthetic appearance and superb load-bearing capabilities, ideal for architectural applications.

- Weldted gratings are celebrated for their robustness and high performance in industrial settings.

- Riveted gratings offer exceptional durability and resistance to impact, making them a prime choice for heavy-duty uses.

Types of Gratings Manufacture and Supplied by Kingdom Grating

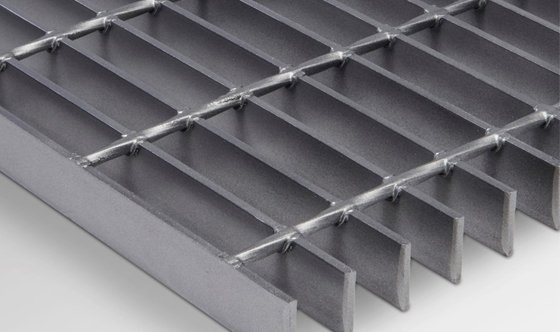

Steel Grating

Durable and versatile, steel grating is ideal for industrial flooring and walkways, offering strength and reliability. Its robust construction ensures it can withstand heavy loads and harsh environments, making it perfect for various industrial applications. Steel grating is also resistant to corrosion and wear, providing a long-lasting solution for areas that require high durability and minimal maintenance. View More

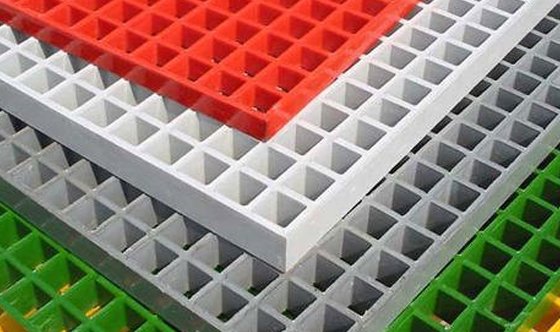

FRP Moulded Gratings

Lightweight and corrosion-resistant, FRP moulded gratings are perfect for harsh environments, providing long-lasting performance. These gratings are easy to install and maintain, offering excellent resistance to chemicals, UV rays, and moisture. They are non-conductive and slip-resistant, making them a safe and effective choice for areas exposed to electrical hazards and slippery conditions. View More

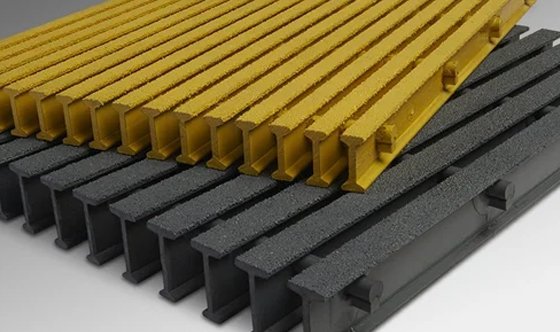

GRP Pultruded Gratings

Strong and fire-resistant, GRP pultruded gratings offer excellent load-bearing capacity and durability for various applications. They are designed for high-strength performance and are suitable for both industrial and commercial use, providing safety and stability. GRP pultruded gratings are also lightweight and easy to handle, making them an efficient option for installations. View More

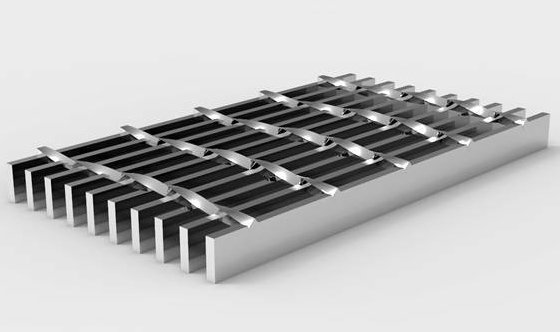

Trench Gratings

Designed for drainage systems, trench gratings efficiently handle water flow while ensuring pedestrian and vehicle safety. They are ideal for use in public spaces, industrial sites, and infrastructure projects, providing reliable drainage and support. Trench gratings are available in various sizes and materials, ensuring they can meet specific project requirements. View More

Press Lock Gratings

Secure and robust, press lock gratings feature a tight fit and high strength, suitable for heavy-duty industrial use. Their precise construction ensures maximum safety and durability, making them an excellent choice for platforms, walkways, and flooring. Press lock gratings are also customizable, allowing for various patterns and configurations. View More

Grating Clamps

Reliable and easy to install, grating clamps secure gratings firmly in place, ensuring stability and safety. These clamps are designed to provide a secure fastening solution, making them essential for maintaining the integrity of grating installations. Grating clamps are made from high-quality materials, ensuring they can withstand harsh conditions and provide long-term reliability. View More

Heavy Duty Gratings

Engineered for maximum strength, heavy-duty gratings support heavy loads and endure tough conditions in industrial settings. They are built to withstand extreme pressure and wear, making them ideal for areas with high traffic and heavy machinery. Heavy-duty gratings offer exceptional durability and performance. View More

Key Players in the Saudi Arabian Market

Leading Manufacturers: Overview of top steel grating companies

Companies like Saudi grate, Grating Manufacturer Saudi, and Emirates Steel are some of the prominent names that have forged strong reputations for quality and reliability in the Saudi market.

Regional Coverage: Which areas of Saudi Arabia have the highest concentration of manufacturers?

The industrial hubs like Riyadh, Dammam, and Jeddah are teeming with manufacturing activities, hosting a large proportion of the country’s grating production facilities.

Market Share and Size: Insights into the dominance of top players

While precise figures are commercially sensitive, it’s clear that the leading firms hold substantial influence over the market, driven by their commitment to quality and innovation.

Innovation and Technology in Fabrication

Recent Technological Advancements: How technology is shaping product quality and manufacturing speed

Innovations such as automated welding and laser cutting have enhanced the precision and efficiency of grating production, enabling manufacturers to meet client specifications with remarkable accuracy.

Customization and Design Flexibility: Exploration of bespoke solutions offered by manufacturers

Companies are increasingly offering tailored solutions, allowing clients to specify the exact size, shape, and material of their gratings to suit specific needs, be it for aesthetic harmony or for specialized industrial applications.

Sustainability Practices: How companies are integrating eco-friendly practices in production

Eco-consciousness is on the rise within the industry, with more manufacturers recycling old gratings and using energy-efficient methods to minimize environmental footprints.

Quality Standards and Compliance

Local Regulations: Overview of Saudi standards for steel fabrication

Saudi Arabia adheres to strict standards to ensure steel products meet safety, quality, and environmental benchmarks, fostering trust and reliability in the marketplace.

International Certifications: ISO and other international compliance that impact manufacturing

Many Saudi manufacturers boast ISO certifications, reinforcing their commitment to global best practices and quality assurance.

Quality Control Processes: In-depth look at the measures ensuring product quality and safety

From raw material inspection to finished product testing, quality control is integral, ensuring that every grating withstands the tests of load, stress, and time.

Challenges and Opportunities

Economic Influences: Impact of global steel prices and local economic policies

Fluctuations in global steel prices and changing local economic strategies continually reshape the landscape, presenting both challenges and opportunities.

Logistics and Supply Chain: Challenges in raw material supply and finished product distribution

Navigating efficient supply of materials and ensuring timely delivery of finished products remain critical hurdles, compounded by geopolitical and logistic variables.

Future Trends: Potential growth areas and emerging markets for steel gratifications

Emerging technologies and expanding industrial sectors hint at new growth avenues for steel gratings, particularly in sustainable and technologically integrated applications.

Conclusion

As we wrap up, it’s clear that Saudi Arabia’s steel gratings manufacturers are not just key industrial players; they are pivotal to the country’s infrastructure and its future growth. With continuous advancements and a firm commitment to quality and sustainability, the horizon looks promising for this vital industry.

FAQ Section

- What are the primary applications of steel gratings in industrial settings?

Typically, they are used in platforms, walkways, drainage covers, and barriers offering strength and safety. - How do international standards impact steel grating manufacturing in Saudi Arabia?

They ensure products meet precise safety, quality, and environmental requirements, enhancing global competitiveness. - What are the environmental considerations for steel grating production?

Eco-friendly production techniques and recycling of materials are key focuses in reducing environmental impacts. - Which type of steel grating is most suitable for heavy industrial use?

Riveted gratings, owing to their durability and resistance to vibration, are ideal for heavy industrial applications. - How can businesses choose the right manufacturer for their needs?

Consider factors like product range, compliance with standards, manufacturing technology, and the ability to provide customized solutions.

Steel Gratings Suppliers & Manufacturers in Saudi Arabia

Searching for reliable steel grating suppliers and manufacturers in Saudi Arabia? Kingdom Gratings, Saudi Arabia top-rated steel gratings are designed for strength and durability, perfect for industrial, commercial, and residential applications

View More

FRP Handrails suppliers & Manufacturers in Saudi Arabia

Looking for reliable FRP handrails suppliers and manufacturers in Saudi Arabia? Kingdom Gratings, high-quality FRP handrails are known for their durability, lightweight nature, and resistance to corrosion, making them ideal for various.

View More

FRP Ladders suppliers & Manufacturers in Saudi Arabia

Welcome to a complete guide where we explore the world of Fiber Reinforced Plastic (FRP) ladders in Saudi Arabia. Whether you’re a buyer, a business owner, or just intrigued by the latest in industrial advancements, this article is your go-to resource.

View More